Wireless Torque Sensor telemetry from the expert – Maintenance- and failure-free with high accuracy

MANNER Sensortelemetrie offers sensor telemetry for the contactless data transmission of rotating transducers for more than 28 years now. All physical measured variables can be acquired and transmitted maintenance-free inductively with high data rates and complete transmission reliability of rotating transducers. Whether on the test bench or in real environments – today’s high demands on power density and durability place maximum demands on technical measurements. High temperatures up to 200° C, high accelerations due to high speeds (> 100.000 g), electromagnetic compatibility and last but not least a very limited installation space. This is where the strengths of MANNER Sensortelemetrie come into full play.

Today, we want to present you the news from our torque sensor department.

XTREMA Two Range Torque Meter-Two Range Torque Transducers from MANNER

MANNER now offers the new “XtreMA two-in-one” dual-range torque transducer for measuring several rotating torque ranges as the requirement to measure different load ranges with one measuring element is rising.

This transducer has two torque ranges with two separate and independent signal outputs. Both the nominal measuring range and the spread measuring range have been optimized in terms of accuracy. Two calibrations and corresponding calibration protocols are created for the transducer. This allows torque around zero to be measured with particular precision. Both the zero drift Tk0 and the characteristic drift Tkc are minimized to the respective measuring range and the temperature.

This means that the “XtreMA two-in-one” can be used over a much wider torque range with the highest accuracy and resolution. The engineer can freely decide which channel is used for the corresponding measuring task.

Overall, this enables the tasks of nominal torque acquisition as well as friction power measurement with one measuring device without modifications in the drive train. This saves time, costs and minimizes the risk of making mistakes. The accuracy of our transducers is verified by our new calibration laboratory – which is certified according to DAkkS.

This new transducer is tough.

With an overload rating of 400%, the torque sensor offers both, the measurement of continuous loads and the short-term detection of load peaks in dynamic operation.

Despite this new technology, the stator antenna remains compact and in the familiar design with an air gap of up to 10 mm in the standard version. However, if requested 40 mm are optional available.

The corresponding stator unit in tube design allows for the detection of the classical analog signals with 0… ±10V / 4..20mA and the frequency output, as well as the output of digital signals via EtherCAT, CAN, Ethernet or USB.

XtreMA Torque – evaluation unit now also with standard frequency output 60 kHz+/-30 KHz

The XtreMA Torque series from MANNER was specially developed as a short design with low rotor weight and mass moments of inertia. This is particularly important for electric motor test benches with nominal speeds of up to 30,000 min-1, especially as the speed requirements there will continue to increase. The test bench operator is thus well prepared for future requirements. The DIN flange pattern used is compatible with HBM torque sensors and allows easy integration into new and also already built test benches with existing infrastructure.

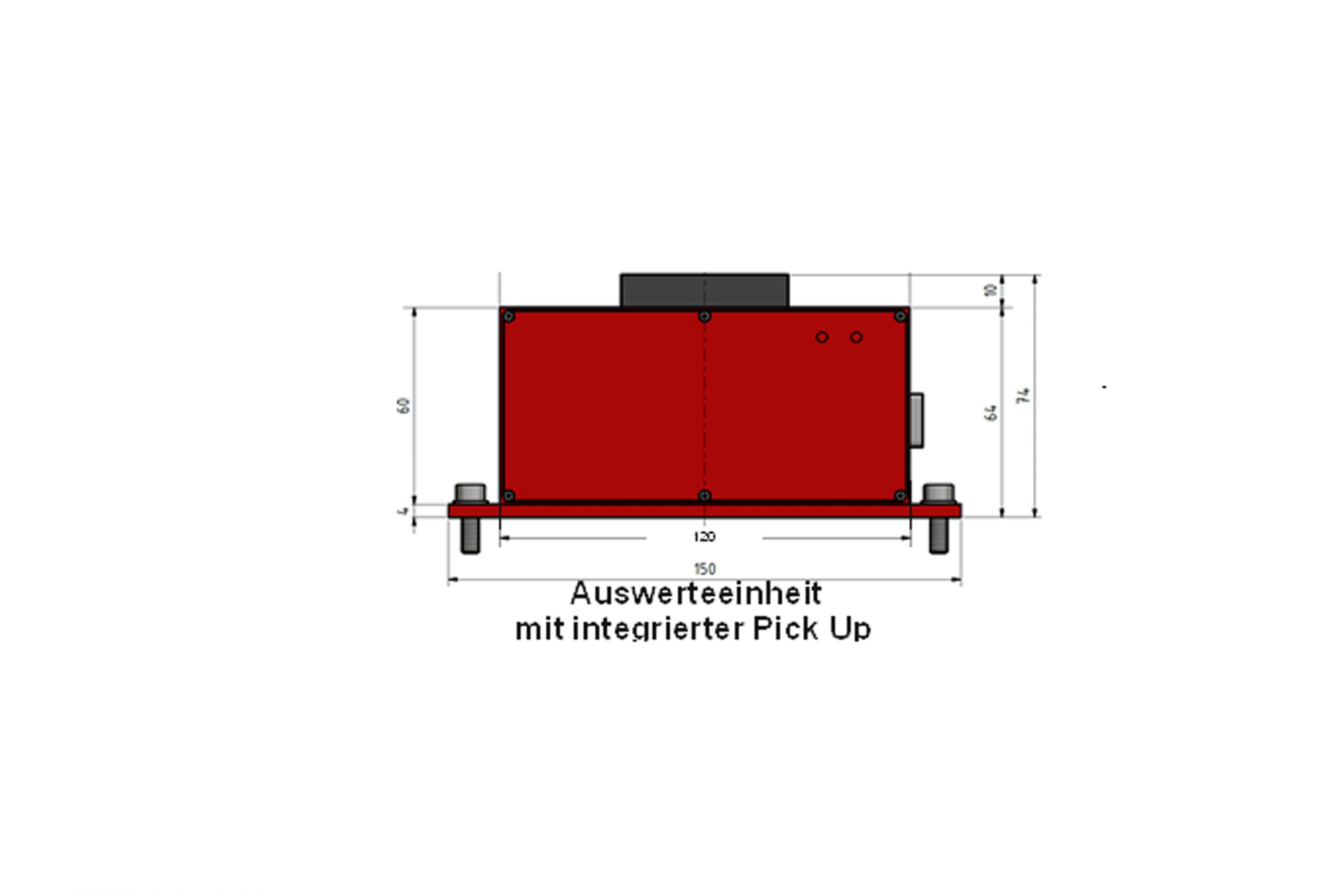

Figure 2: XtreMA Torque Sensor and evaluation unit with integrated pick-up (distance up to 10 mm)

What should be emphasized is the simplicity of the evaluation unit developed for the XtreMA series. The nominal distance between the torque flange and the evaluation unit of up to 10 mm makes installation particularly easy. The large distance using inductive power supply and data transmission also prevents the evaluation unit from being damaged by possible string vibrations. It is not necessary to enclose the pick-up on the flange. In addition, the LEDs on the evaluation unit directly indicate the functionality of the system during installation to support the user. The compactness of the evaluation unit also supports the ease of integration on the test bench. With 64x120mm, the necessary space can be found in almost every test bench concept.

The MANNER XtreMA evaluation unit is compatible with all 1-channel customer-specific torque transducers (increased speeds; temperatures; special flange patterns or force influence resistances) from MANNER and is therefore a modular system component in the MANNER portfolio.