DAkkS Torque Calibration Laboratory– Reproducibility and cost reduction through automation

MANNER Sensortelemetrie has created a new dimension of quality through replicability due the brand-new automated process of torque calibration. The achieved cost savings and improved lead times benefit our customers as well.

Motivation – Customer need of faster and more cost efficient calibration

Torque measuring remains the critical parameter to determinate load spectrums, efficiency factors, validation of consumption data and for process monitoring. Due to increasing formalities for climate protection (Dieselgate), more precise and traceable calibrations of measuring feeders are required. This additional requested calibration of measurement equipment affects all industries. To address this request, MANNER is in the process to acquire the DAkkS-Accreditation.

This results in the demand for high-quality, yet cost-effective calibrations with short delivery times for a wide variety of torque transducers such as gear shafts, side shafts, flexplates or measuring flanges for test bench applications – as initial or recalibration..

For MANNER as a manufacturer of torque transducers and calibration service provider, this means that higher throughput and lower prices must represent a reference for the customer.

Challenges

The quality of a calibration represents the highest premise. The process of calibration with all steps, such as the calibration point approach including evaluation, is not only a labor-intensive work step, but can also be evaluated in manual form as a source of error with lower reproducibility.

MANNER 2018 has set itself the goal of automating this process right up to the creation of the protocol. A calibration automation system was developed for the complete portfolio from 100 N·m to 500 kN·m, which reduces personnel deployment and throughput times.

In addition to the different measuring ranges at MANNER, a particular challenge for automation is the diversity of the transducers – from the soft cardan shaft to the torsional stiff torque transducer. Rotation angles from 1 to 60 degrees can be covered by automatic systems with efficient cycle times without endangering the transducers.

Solution

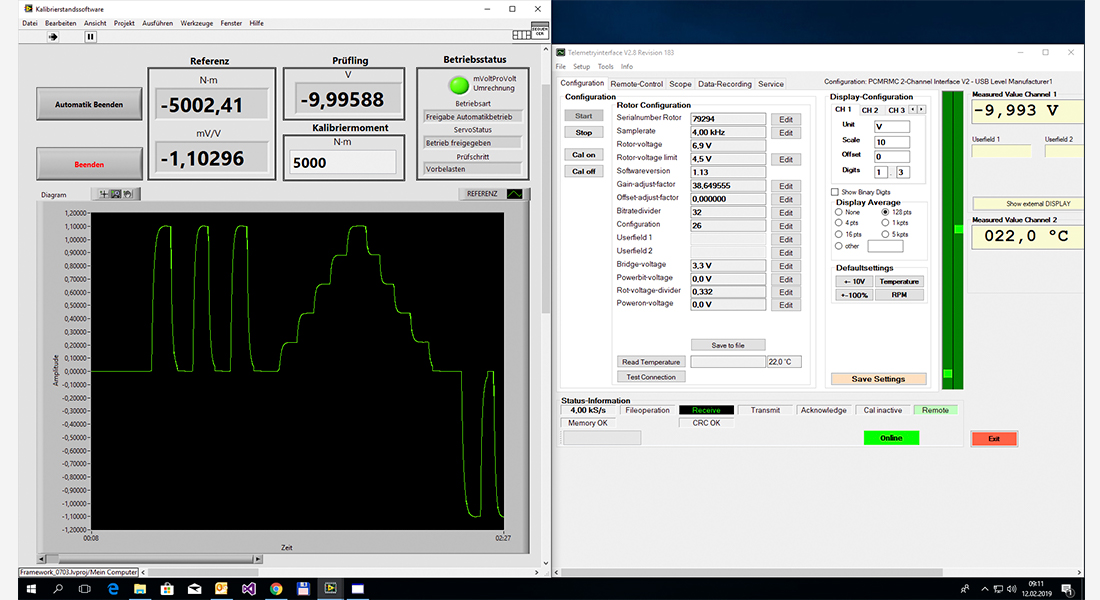

Conversion to new electric motors and modern SPS programming as well as extensive testing to determine the required parameters allowed MANNER to automate the calibration equipment.

Figure 1: Automation software and MANNER telemetry interface

This enables the quality characteristic of reproducibility to be achieved, as well as the reduction of throughput times and the associated reduction in personnel deployment. MANNER also passes this further development on to its customers. Feel free to ask your transducer!

In the next step, calibration at different temperatures will be automated as a special feature – this will enable this service to be offered with shorter throughput times and lower costs in the future. With the appropriate correction electronics, it is thus possible to guarantee consistently high accuracy of the sensor over the entire ambient temperature range.

Our portfolio:

- 10 – 200 N·m

Test bench for miniature transducer applications, e.g. for spindles. - 1 kN·m test bench

Test bench for customer-specific transducers such as pulleys and flanges with a calibration range of up to 1 kN·m. - 5 kN·m test bench (Quantity: 2)

Test bench for flanges as well as side shafts, gear flanges or e.g. distributor shafts for aircraft landing flap systems. Due to the variable adjustment of the length, both short flanges and measuring sensors with lengths of up to 3 m can be calibrated. - 50 kN·m test bench

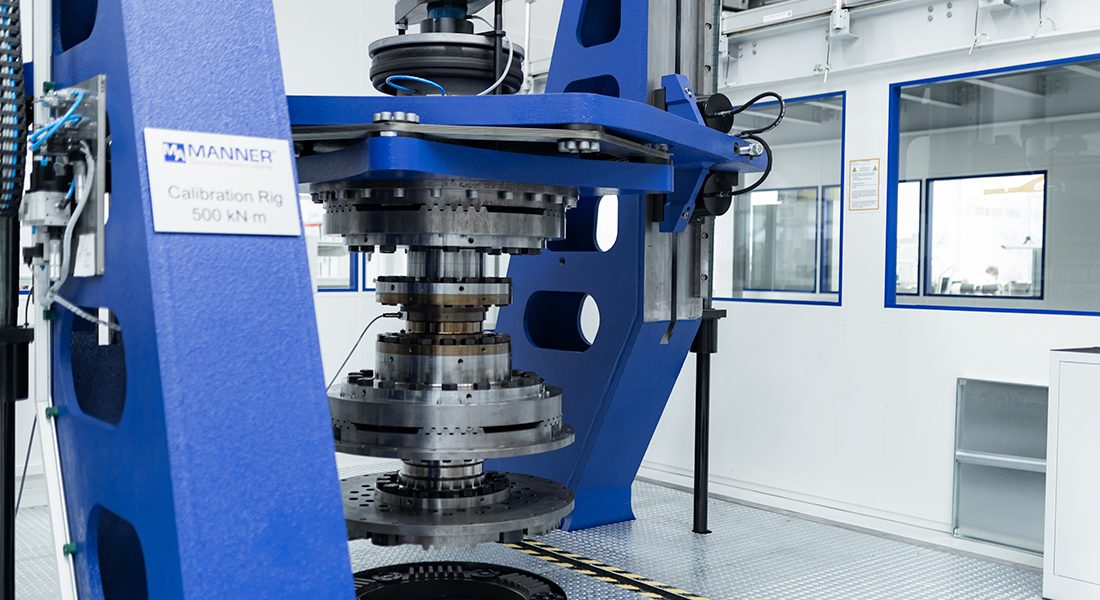

Vertical inline test stand, mainly for flange applications, for truck and heavy machinery test stands. The generous vertical radial peak dimension even allows the calibration of bulky special transducers. - 500 kN·m test bench

Test bench for standard torque transducers and special transducers for shipping, large gears or wind turbines, which can be manufactured and/or calibrated by MANNER.