Two Range Torque Meter – Made by MANNER

The requirement to measure different load ranges with one measuring element is becoming more and more common. Friction losses are particularly important for optimizing fuel consumption. These are often detected during partial load operation, which means operation with low torque. The transducer designed for the maximum torque is usually much less accurate in the partial load range. On the other hand, exchanging the torque transducer for a torque transducer with an adapted measuring range is undesirable due to the assembly effort. This Problem has now been solved in an extremly convenient way.

MANNER offers the new two-range torque transducer “XtreMA two-in-one” for the detection of torque on rotoarting parts.

This transducer has two torque ranges with two separate and independent signal outputs. Both the nominal measuring range and the zoomed measuring range are optimized with regard to accuracy. Two calibrations and corresponding calibration protocols are created for the transducer for analysis and evaluation. As well the zero drift Tk0 as the characteristic drift Tkc is minimized over the temperature to the respective measuring range. This means that the “XtreMA two-in-one” can be used over a significantly larger torque range with the highest accuracy and resolution.

The user can decide which channel is to be used for the corresponding measurement task.

The tasks of nominal torque measurement as well as friction power measurement can be solved without modifications in the drive train using a single measuring device. This saves time, costs and minimizes the risk of making mistakes.

The accuracy of our transducers is proven by our new calibration laboratory, which is certified according to DAkkS. Moreover, MANNER offers full-service DAkkS and factory torque calibration from 10Nm – 500kNm as well as axial force calibration. With the internal resources created, MANNER is able to achieve outstandingly short delivery times.

This new transducer is tough.

Due to the overload design of 400%, the torque sensor offers both the measurement of continuous loads as well as the short-term detection of load peaks in dynamic operation. Despite this new technology, the stator antenna remains compact and in the familiar design with an transmission distance between rotating part and the pick up of up to 10 mm in the standard version.

This has proven to be extremely advantageous in practice, as mounting errors or vibrations of the pick up won’t lead to a worst case szenario. In addition, even imprecise mounting does not pose a challenge for transmission quality. The corresponding stator unit in tube design allows, in addition to the classic analog signals with 0… ±10V / 4..20mA or the frequency output, the output of digital signals via EtherCAT, CAN, Ethernet or USB.

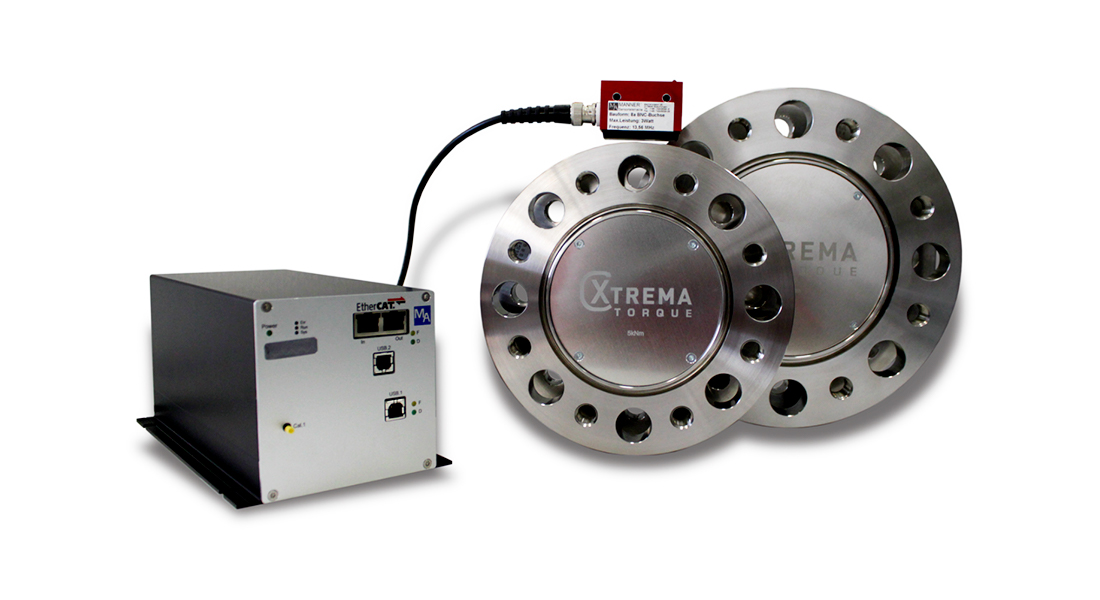

Figure 1: MANNER pick-up remote with tube evaluation unit for installation in control cabinet

Alternatively, MANNER also offers a compact evaluation unit with and without speed measurement. The alignment of the speed sensor via LED signal is a very easy plug & play solution. The temperature stability with remote pick up allows operation under the toughest environmental conditions from -40°C to +160°C. The “hollow shaft” option allows complex test bench concepts. The oil supply in the centre or actuator is no show stopper. On request, the XtreMA torque sensor is available with and without speed measurement.

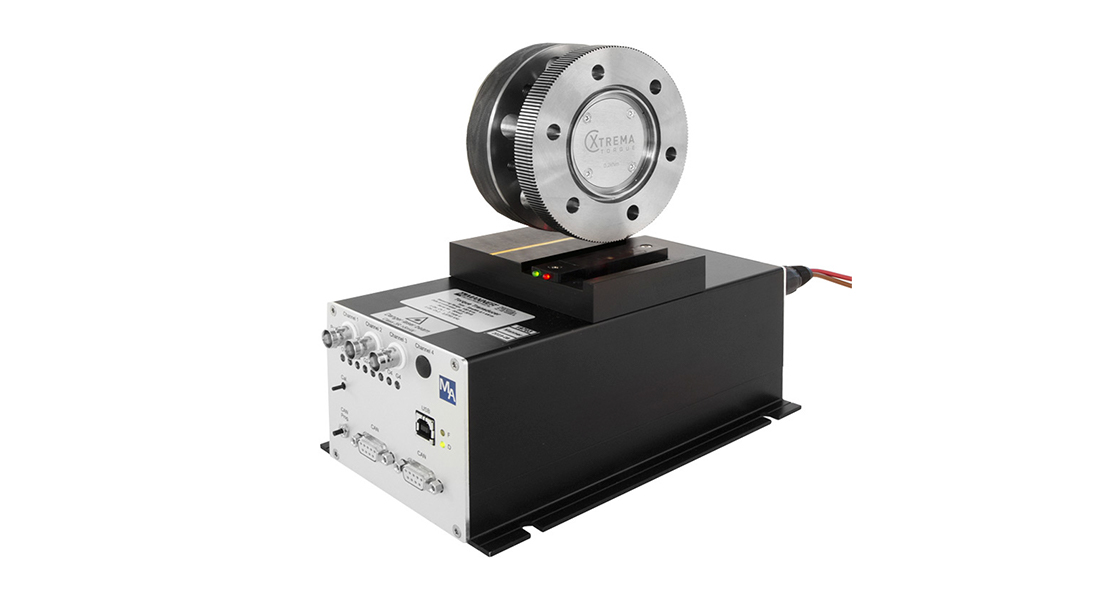

Figure 2: MANNER XtreMA torque sensor with compact tube evaluation unit and integrated antenna with speed laser

The series is available in versions of 50 N·m; 100 N·m; 200 N·m; 500 N·m; 1 kN·m; 2 kN·m; 3 kN·m; 5 kN·m; 10 kN·m.

MANNER – Technology for maximum accuracy over the entire temperature range

High-precision measuring equipment is required for test bench operation for testing combustion engines, hybrid and electric motors. As is well known, the class accuracy is only defined for an ambient temperature range of 22°C +/-10°. Outside this temperature range, the error is significantly higher. The new optional compensation technology for Tk0 and Tkc guarantees the specified class accuracy over the entire specific operating temperature range (-40..+160°C). This means that even outside the temperature range of +/-10 °C defined by the class accuracy, there is no deterioration. In addition, the new compensation technology for Tk0 and Tkc provides guaranteed high class accuracies of < 0.01.

Friction power measurement in particular makes high demands on the measuring equipment. In order to meet these requirements, the transducer has a standard accuracy class of 0.05. The “High precision variant” with accuracy class 0.01 is available for special friction power measurements. This variant is in no way inferior to the HBM T12.

XtreMA Torque – The standard transducer for extreme challenges

The XtreMA Torque series from MANNER was specially developed as a short design with low rotor weight and mass moments of inertia. This is especially important for electric motor test benches with nominal speeds of up to 30000 min-1, all the more so as the speed requirements there will continue to rise. Thus the test bench operator is well prepared for future requirements.

The high nominal speeds of up to 30000 min-1 are no challenge for the XtreMA Torque. The used DIN flange pattern, which is compatible with HBM torque sensors, allows easy integration into new test benches as well as already installed test benches with existing infrastructure.