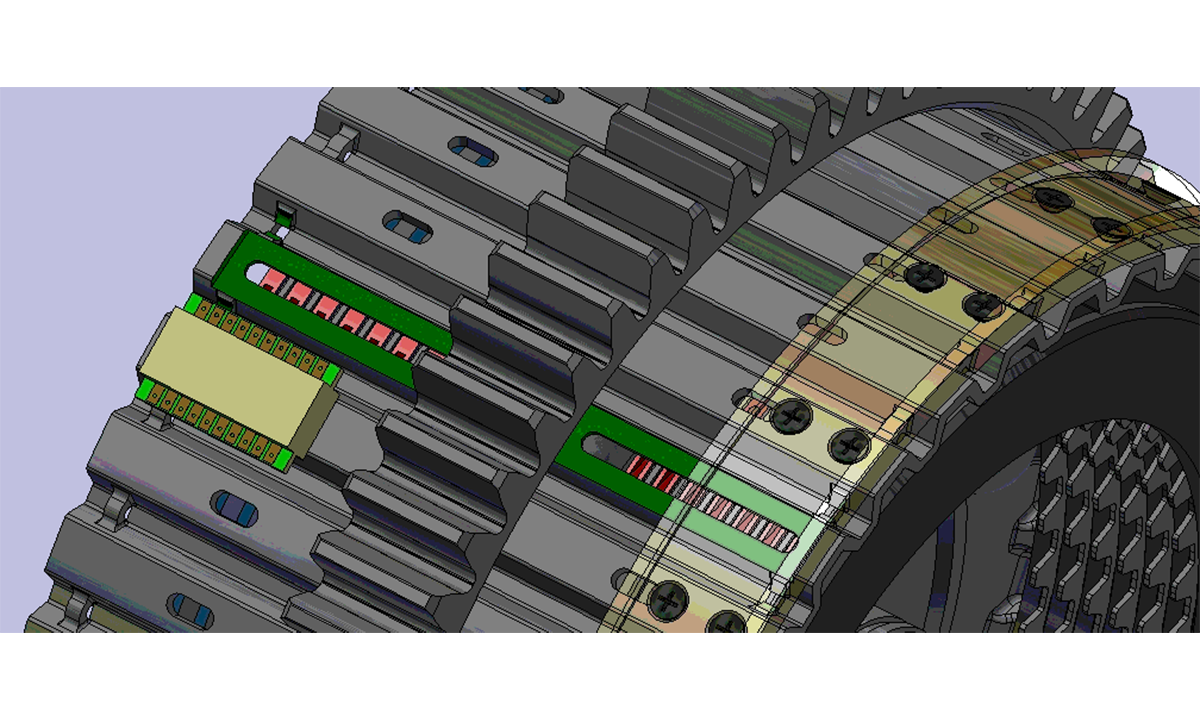

Thermal validation of clutch plates –

with 200°C temperature telemetry

Temperature detection in the vehicle is becoming increasingly relevant. The development of hybrid vehicles or pure electric cars is in focus.

Developers are facing new challenges as a result of the conversion of the drive concept to electric motors. In contrast to the combustion engine, there is no self-locking of the drive train in the electric drive when the engine is switched off. This is why parking locks are also needed for purely electric cars.

Despite the high torques that occur, the parking lock should be compact. Because of their compact design, only wet clutches are suitable. The classic dry clutches from the combustion engine sector are not suitable and also suffer from abrasion. However, adjusting the preload of the clutch packs in wet clutches is a sensitive process, since the resulting frictional power in the transition process (driving-stationary) can cause enormous heat input. This is why this point is the focus of the investigations. In hybrid vehicles, too, wet clutches are often integrated and interleaved. Usually, several drive motors are connected together via clutches, depending on the operating situation. The power of the electric motors is switched in place of the combustion engine or as an add-on to it.

Another interesting application is wet clutches for torque vector rings. This can significantly improve driving stability.

Thermal validations of the wet clutch – especially of the clutch plates – under real operating conditions are a must to ensure long-term operational stability.

In order to determine the long-term operational stability of critical and high-value components, such as couplings, and also to exclude friction power losses or overloads during operation, the miniaturized temperature measuring point with non-contact and robust measurement data transmission from MANNER represents the central means.

Challenge

Space conditions are particularly challenging at coupling measuring points. Here it is difficult to find adequate space for telemetry technology.

In some concepts, the coupling with the electric motor is already fully integrated, which means that there is de facto no space for measurement technology. In addition, many metrological solutions on the market are not robust against the often obvious electric motor, as well as the environmental parameters such as temperature, vibrations and high speeds.

The tight space conditions allow thermal validation only through robust, temperature-resistant and above all miniaturized sensor telemetry with a flexible transmission concept of energy and sensor data from coupling measuring points, as well as the corresponding application know-how.

The operationally stable installation of miniaturized thermocouples also presents a particular challenge, since the coupling pacts also perform a relative movement. There must be hardly any mechanical processing of components, such as the coupling, which would weaken the mechanical parts. In addition, existing oil holes must be further accessible in order to test the real condition and the operational stability in a lifelike manner.

Full-Service Plug and Measure

MANNER’s measurement technology takes on the challenges posed by these applications and also offers its customers the full-service plug and measure concept if required. MANNER Sensortelemetrie thus offers an all-inclusive package based on 30 years of experience.

Depending on the requirements, a typical 8-channel temperature measuring amplifier with the compact dimensions of 21 x 12 x 5 mm and weighing only 3 g can be used for wet clutches. For clutches on purely electric vehicles for parking barriers, the 1-channel solution using a flex amplifier or a miniature chip measuring 6 x 24.8 x 3.5 mm is often used. All solutions are cascadable and can therefore also be integrated as multi-channel solutions with a wide variety of geometries in the available space. Multi-channel solutions can thus be implemented with any form factor.

The high operating temperature resistance of 200°C for the measuring amplifiers is also decisive.

MANNER Sensortelemetrie offers a robust transmission method that has been tested in over 1,000 applications and can be flexibly adapted to the space available. The flexible energy and data transmission by means of copper rings and coils also provides innovative application possibilities, which are also demanded by the increasingly compact developments of these vehicle components.

The challenging installation of thermocouples for high operational stability is special know-how at MANNER. This experience is based on many applications with up to 24 measuring points per application. This know-how extremely reduces the risk of losing a measuring point. The load on rotating measuring points is extremely high and cannot be compared with static measuring points, e.g. on the housing. A defective thermocouple means that the complete measuring point is lost or can only be repaired with very high effort, such as the disassembly of the coupling, as well as the replacement of the lamella with a new thermocouple. In addition to the know-how of the installation, the thermocouples for such applications are also developed by MANNER and are refined with special testing and manufacturing processes.

As an experienced full service and measure provider for clutch solutions MANNER does not only offer a technical product. As an experienced partner, MANNER offers the full service package from 3-D design for solution finding, integration of sensor telemetry to the integrated plug and play system on your test bench or in the vehicle for direct reading of your temperatures.

Our know-how with over 30 years of experience

MANNER is a specialist in non-contact measurement data transmission with the unique selling point of robustness and temperature resistance up to 200°C electronics temperature. As a service provider for measurement applications, MANNER offers the full service Plug and Measure and also telemetry for self-application.

The runtime of the system is unlimited due to the inductive and maintenance-free patented sensor telemetry transmission technology.

As standard, we work with robust thermocouples developed in-house, which effortlessly withstand the increasing degree of vibration. The processing and installation technology is based on years of know-how.