Condition Monitoring Sensor TelMA - Torque, temperature and speed now also with Ethernet interface

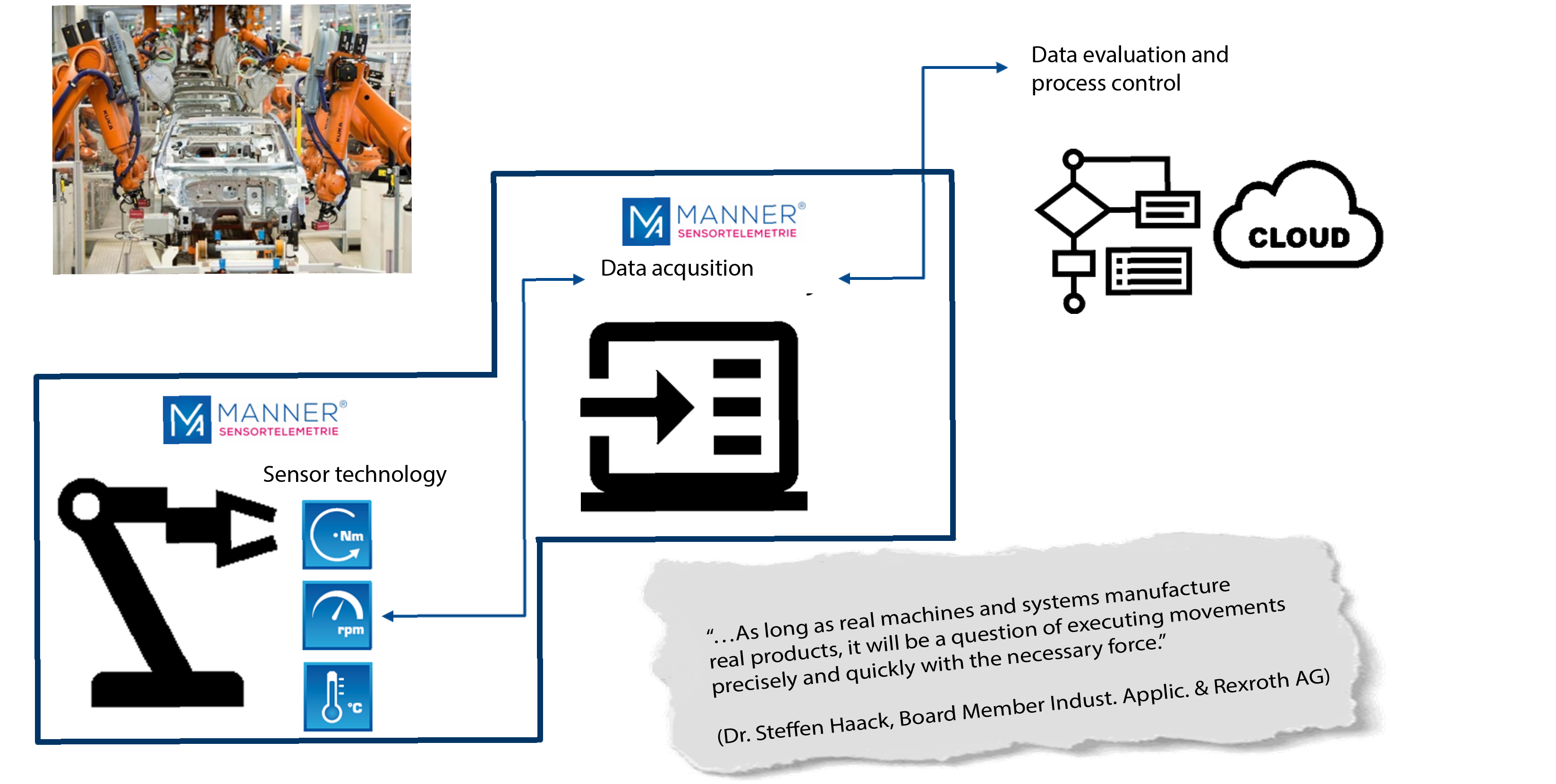

The Industry 4.0 product lines with weldable torque sensor have now been expanded to include an Ethernet interface. This makes it even easier to integrate the central control variables torque, temperature and speed into the control process.

The Ethernet interface offers maximum flexibility – in addition to the output interface, the analogue outputs (current & voltage, CAN) are also integrated.

Both product lines TelMA and TelMAX offer this new feature with the aim of simplifying the integration of sensor technology for the control of machines and plants.

TelMA and TelMAX, the core of all goodness:

The core of the product lines is the TelMA sensor, which combines the proven properties of strain gauge technology and near-field telemetry. All this combined with a cost-effective application technology results in a torsion sensor in postage stamp format.

Contrary to many other sensor solutions, this application is particularly suitable for integration into existing constructions (retro-fit).

The high flexibility of the inductive and maintenance-free antennas and the detection system with interfaces for process control successfully round off the product.

Simplest assembly guaranteed:

No soldering iron or gluing process is required for assembly. Thus, there is no need for curing of the connection technology and the set-up is immediately stable in the long term. An application in the product line can be realised in less than 3 minutes.

Torsion sensor with integrated telemetric interface (35.53 mm x 18.1mm x 6.25 mm)

Plug and Measure:

The system can be used directly and, if necessary, still configured (sensor name, sample rate, information deposit etc.) and calibrated (zero point and gain settings) by the MANNER software “Telemetry Interface”.

Your advantages at a glance:

– large transmission distance (shaft – stator unit)

– insensitive to magnetic fields

– no problem with shaft currents in hybrid or electric drives

– free choice of material (no need for ferromagnetic materials)

– no influence of shaft displacements/radial oscillations on the measuring signal

– good measuring signal quality even with low torsional stresses

– Higher accuracy by a factor of ten than with magnetic methods

If you have any questions or enquiries, please do not hesitate to contact us at info@sensortelemetrie.de or phone +49 7424 93 29 – 0.