Revolutionary range extension for side shaft applications with MANNER Sensor Telemetry

MANNER Sensor Telemetry has significantly increased the range of inductive data transmission on side shafts – Take a look at our application film and the usage report from our customer FEV!

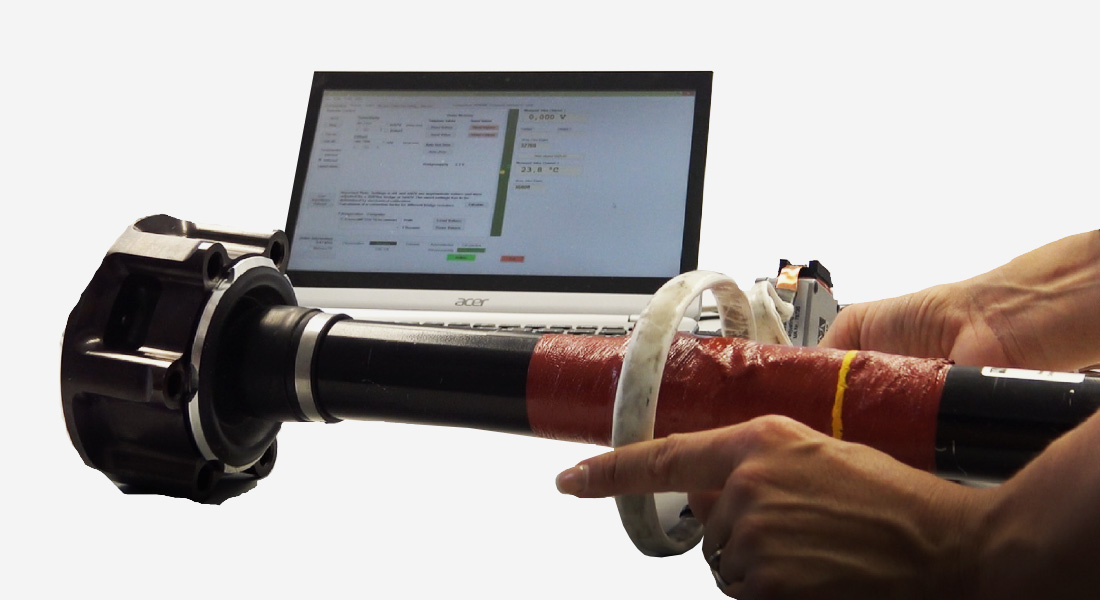

Measurement on side shafts

The side shaft establishes the dynamic connection between the gearbox and the drive wheels. It transmits the power during the simultaneous movement of the steering and suspension. With its two constant velocity joints, it functions in parallel as a vibration damper. Each side shaft is equipped with a fixed joint at the wheel end and a slip joint at the gearbox end which are both connected by the so-called intermediate shaft.

Measurement on the side shaft using MANNER Sensor Telemetry helps you precisely measure torque and dynamic drive power as well as its distribution. The impacts on efficiency, dynamics, noise, vibration and driving behaviour can also be observed in addition to weight optimisation and service life.

Challenge

Whether in motorsport or on the test track, reliable data transmission during measurement is of the utmost relevance.

Due to time pressure on the test or race track, it is often not possible to give measurement technology the utmost attention. That is why integration must take place quickly and be able to forgive user inaccuracies.

This includes, among other things, the application of the flexible stator loop, which is not exactly above the rotor loop marking, or the somewhat looser application of the flexible stator loop, which may slightly shift during driving.

The solution

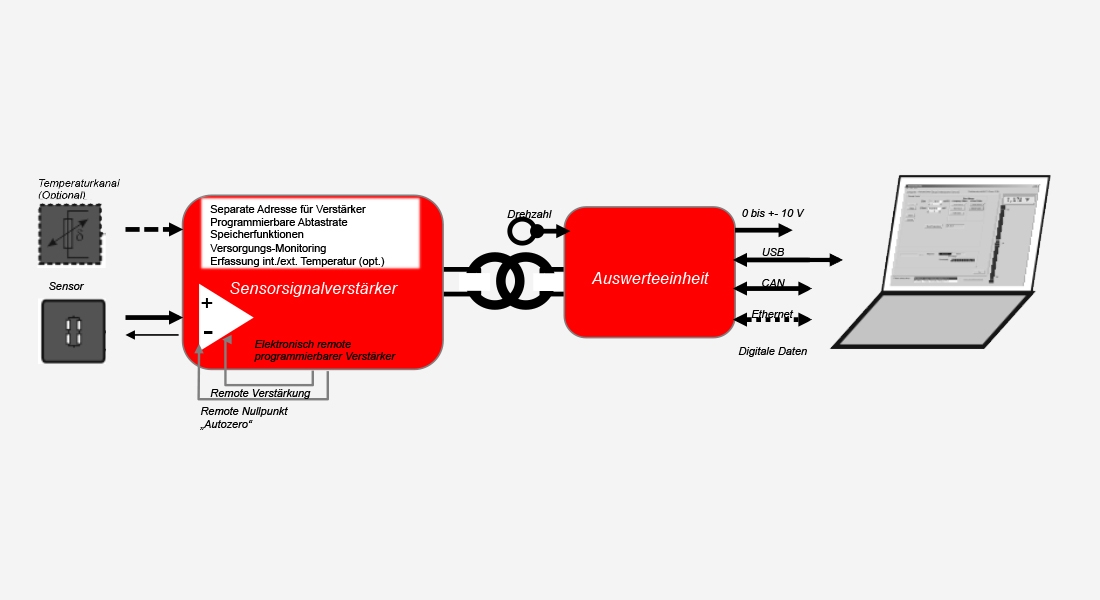

Besides the extreme reliability of data transmission, one of the most important characteristics and, at the same time, challenges of measurement technology is achieving low EMC emissions. By increasing energy in the induction field, other vehicle sensors, e.g. wheel sensors, can be sensitively disturbed. The range extension newly developed by MANNER is not based on an energy increase in the induction field, but on a technological innovation that leads to improved antenna resonance and thus further simplifies the plug & play solution.

As a result of the further development, the flexible stator antenna can be horizontal, far away from the centre of the rotor loop antenna (yellow line), and still ensure optimum data transmission. A measurement result is also guaranteed under harsh operating conditions with high vibrations, in which the fastening loosens. Of course, the increased range is also noticeable in the vertical.

The following figure shows the improved range:

All MANNER benefits available

The side shaft can accommodate the rotor antenna, sensor-signal amplifier and casing within a height of just 4 mm. Since the weight of the telemetry is marginal, the system is not influenced by its own behaviour and the problem of balancing is eliminated. The application is also very robust and well suited for use in extremely harsh environments (off-road testing). The popular remote auto-tuning feature is now also included in the standard version. Therefore, subsequent adjustments can be made to the torque measurement range and the zero point can be adjusted using the remote control feature without the need for a soldering iron.

Easy to replace system components

The system components are fully interchangeable to simplify logistics and reduce system costs. All systems within the vehicle use the same transmission frequency. The synchronization of the receivers – as known with carrier frequency amplifiers – prevents crosstalk and ensures that other sensors are not affected.