Measurement technology in fire – Temperature telemetry 200°C -resistant for couplings, electric motors and pistons

The recording of temperatures on rotating vehicle parts to ensure operational stability is becoming increasingly relevant. The long-term operational stability of critical and high-quality components such as clutches, electric motors and pistons is therefore a particular focus. The temperature impact on the components in the different operating modes has no influence on the functional safety, but on the service life. With this data, friction power losses can be minimised and overloads can be ruled out during operation. The central tool is the miniaturised temperature measuring point with non-contact and robust measurement data transmission from MANNER.

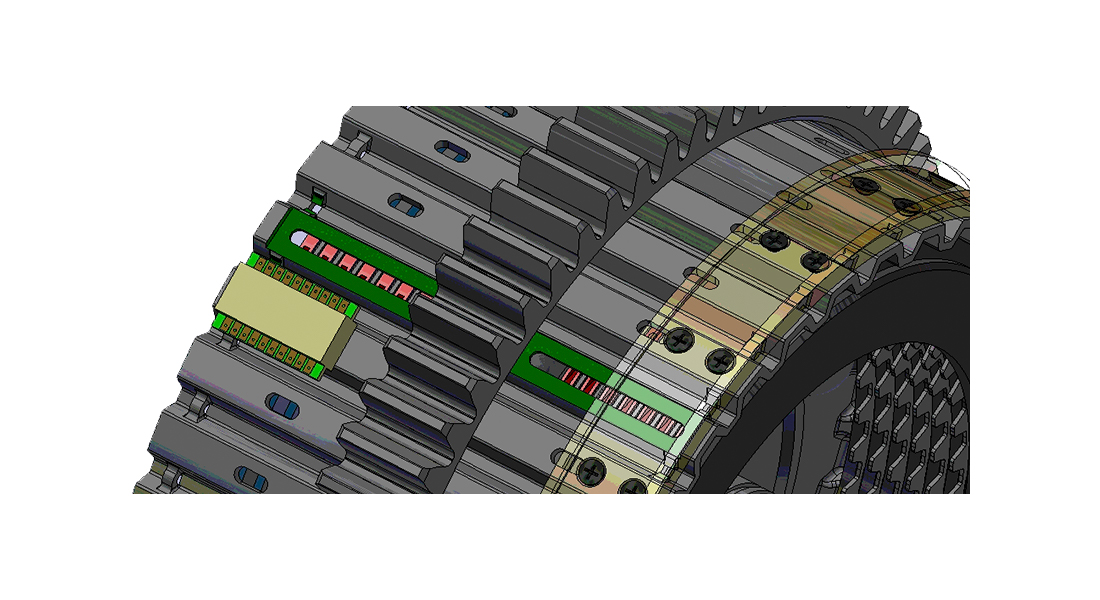

Wet clutches in particular are becoming increasingly integrated and nested, which makes temperature measurement much more difficult. The same applies to electric motors, which in the latest developments are already integrated within the coupling. Thus, there is no space for measurement technology.

Piston development for the increasingly popular hybrid vehicles also needs a reliable, miniaturised measuring device to measure even in the fired engine. This is the only way to optimise the lubrication process after the simulative development and to measure the temperatures on the piston and their distribution under different load scenarios without restricting the piston itself in its functioning.

Challenges

MANNER’s measurement technology accepts the challenges posed by these applications and also offers its customers the full-service plug and measure concept if required.

Measurements in electric vehicles or hybrid vehicles are on the rise. As a result, the measurement technology is often installed close to or even directly on the electric motor in order to measure where the relevant measurement points of the drive concept are located. However, this poses special challenges for the transmission technology. MANNER has developed a robust transmission method that has been tried and tested over a wide range of applications. It transmits high data rates from the electric motor for real-time evaluation and can be operated reliably at 200°C ambient temperature. In addition to the temperature channels described here, other sensors with high data rates can also be connected.

Due to the complexity of today’s wet couplings, 8, 16 and 24 measuring channels are standard and must be installed inside. Here MANNER offers a modular range of measuring amplifiers which can be extended to up to 48 channels.

In addition to operational stability in extreme electromagnetic fields, a high ambient temperature and the high speeds, the installation space represents a particular challenge for integrating measurement technology into the finished series component.

The cascadable miniature measuring amplifiers developed by MANNER – which can be designed with almost any form factor – enable integration into even the smallest installation spaces. Power and data transmission are also carried out with simple copper rings. This allows extremely innovative possibilities for application design, which are indispensable for increasingly compact developments of these vehicle components.

But the operationally stable application of miniaturised thermocouples also poses a special challenge. Even a simple thermocouple can reach its limits on pistons, wet clutches and electric motors due to the high accelerations. In addition, hardly any mechanical processing may take place on components such as the coupling, as this would weaken the mechanical parts inadmissibly. Also, existing oil holes must remain accessible in order to test the real condition and the operational stability in a lifelike manner. In addition to the know-how of operationally stable installation and assembly, the thermocouples for such applications have also been developed by MANNER and are refined with special tests and manufacturing processes.

Our Know-how

As a specialist in non-contact measurement data transmission with a measurement amplifier portfolio with electronic temperatures of up to 200°C and as a service provider for measurement applications, MANNER offers the full service package or just telemetry for self-application.

Miniature measurement telemetry also provides innovative application possibilities, which are demanded by the increasingly compact developments of these vehicle components. The measurement technology follows the design. The typically 9-channel temperature measurement amplifier is extremely compact (21 x 12 x 5 mm) and weighs only 3g. Several components can be cascaded to expand the measuring channels. In addition to this measuring amplifier, there are also others in the portfolio to meet any installation space requirement – please enquire today!

The system’s runtime is unlimited due to the inductive and maintenance-free patented sensor telemetry transmission technology.

We work with self-developed robust thermocouples as standard, which effortlessly withstand the increasing degree of vibration. The testing, processing and laying technology is based on many years of know-how.