The temperature measurement of the rotor or its windings plays a decisive role in the safe operation of (large) electric motors and generators. When converting kinetic energy into electrical energy or vice versa, it is urgently necessary to avoid thermal overloads and their devastating consequences. Furthermore, from an economic point of view, it is desirable to extend the replacement and maintenance intervals or to adapt them to the specific load situations.

With the help of MANNER Sensortelemetry, measuring the rotor temperatures becomes child’s play. To protect against exceeding the permissible rotor and winding temperatures, we have been working for many years with manufacturers and operators of electric motors and generators to optimize the monitoring of thermal loads. Furthermore, you are thus able to match the maintenance of your rotor configuration to the real demands and automate the monitoring processes.

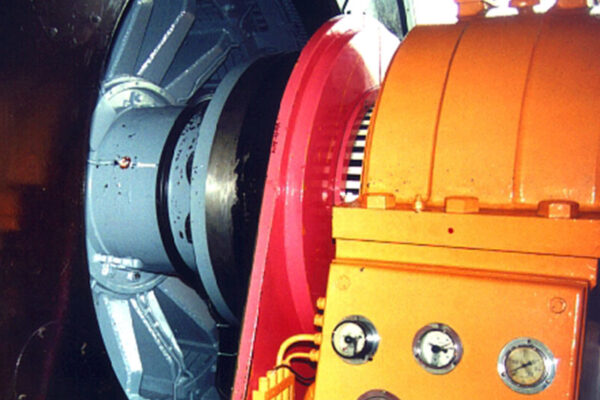

In doing so, we guarantee the highest immunity to interference in data transmission; even in extreme electromagnetic interference environments. Our rotor temperature recording systems based on non-contact sensor telemetry are used successfully worldwide in power plants, railway converters, steelworks, oil pumping stations, etc.