High precision torque transducers for maximum efficiency in vehicle development

In the wake of CO₂ discussions, the requirements for the accuracy and resolution of torque measurement signals are constantly increasing. Precise torque transducers are essential for optimizing efficiency in particular, in order to ensure dynamic torque measurements with maximum accuracy.

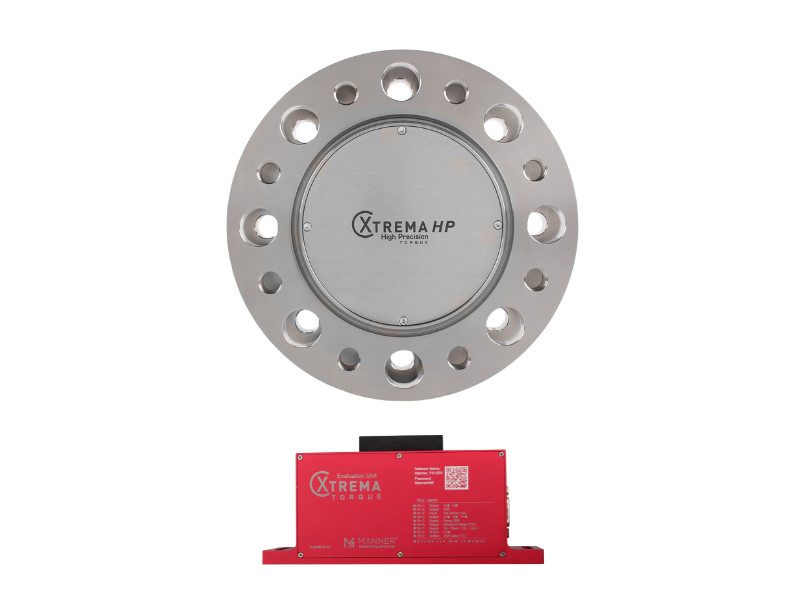

The solution: XtreMA high precision torque transducers from MANNER

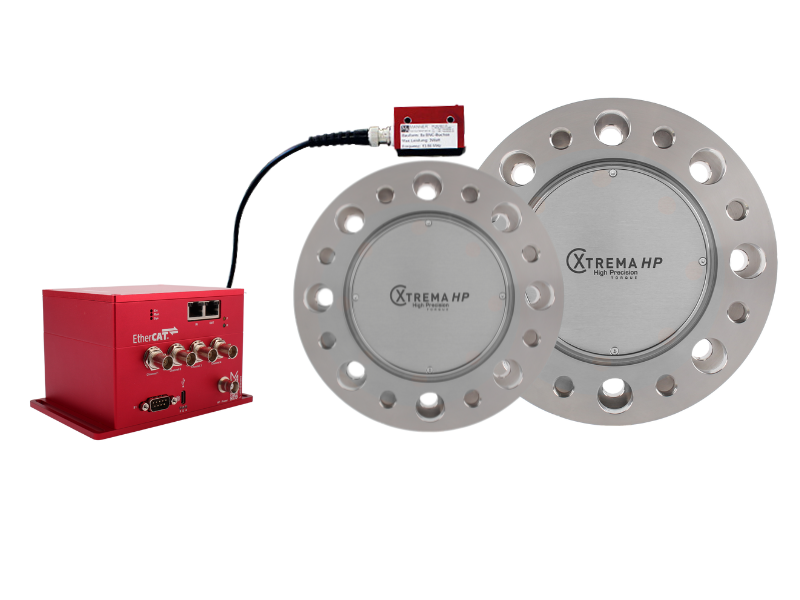

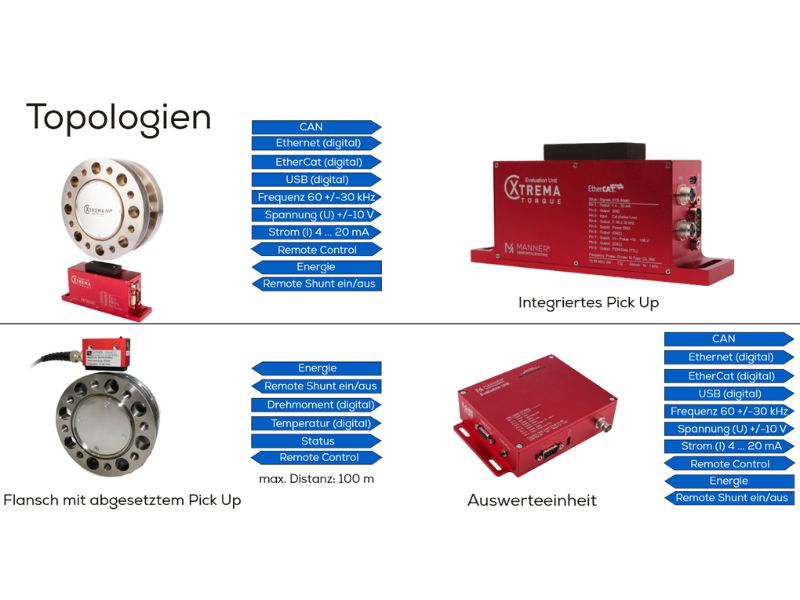

With the new XtreMA high precision product range, MANNER Sensortelemetrie offers an innovative solution for highprecision torque measurement. These torque transducers impress with maximum measurement accuracy, flexible application options, and easy integration into existing test bench systems.

Torque transducers as test bench measuring equipment for combustion engines, hybrid and electric drives

Precise torque measurement is a key factor in the development of combustion engines, hybrid and electric modules – especially on test benches for validation. As optimization potential becomes increasingly refined, high-resolution torque transducers are required to measure even the smallest increases in efficiency.

The new XtreMA high precision TORQUE series offers an improved alternative to conventional torque flanges. It enables precise measurements under real test conditions – from idle to partial load to full load and across a wide operating temperature range.

Flexibility and easy integration into test benches

A key advantage of the new torque transducers is their high flexibility. Thanks to the DIN flange pattern used, which is compatible with HBM torque sensors, the sensors can be easily integrated into existing or new test bench concepts (retrofit).

The optional hollow shaft design offers additional scope for coaxial drive concepts. This allows additional drive trains or cables to be routed inside the measuring flange – a decisive advantage for modern test benches.

Conclusion

The new XtreMA high precision product series from MANNER sets new standards in torque measurement. These high precision torque transducers not only offer maximum accuracy, but also maximum flexibility for a wide range of test bench applications.