As complex and specific as industrial plants and production facilities are structured, MANNER manufactures the appropriate measuring applications for tough continuous operation. In the field of oil-free gas and air compression as well as in the application field of extruder screws, the most accurate recording of torques, forces and temperatures is ensured by the contactless transmission of measurement data in our sensor telemetry applications. Long-term monitoring of extruder shafts thus becomes as easy as automated machine monitoring of thermal loads.

MANNER Process Monitoring

Precise telemetry measurement systems for the most demanding requirements

Efficient process monitoring for the protection of automated production facilities

MANNER Sensortelemetrie GmbH offers miniaturized measurement applications for the precise recording of a wide variety of drive performances for reliable monitoring and damage prevention in automated production facilities. Our innovative process monitoring allows the load limits of individual components to be detected at an early stage and production operations to be stopped automatically and without disruption in the event of critical exceedances.

Our customized solutions for early damage detection and prevention are developed for a wide range of production facilities, industries, and manufacturers. MANNER’s easy-to-install measurement systems make a decisive contribution to optimizing production facilities in terms of service life, strength, efficiency, and effectiveness—for maximum operational safety and performance.

Modern extruders require innovative gear technologies that distribute maximum torques evenly across all screw shafts in a confined space. MANNER’s sensor telemetry is used to precisely measure the actual torques. This allows all relevant parameters of the extruder control system to be optimized.

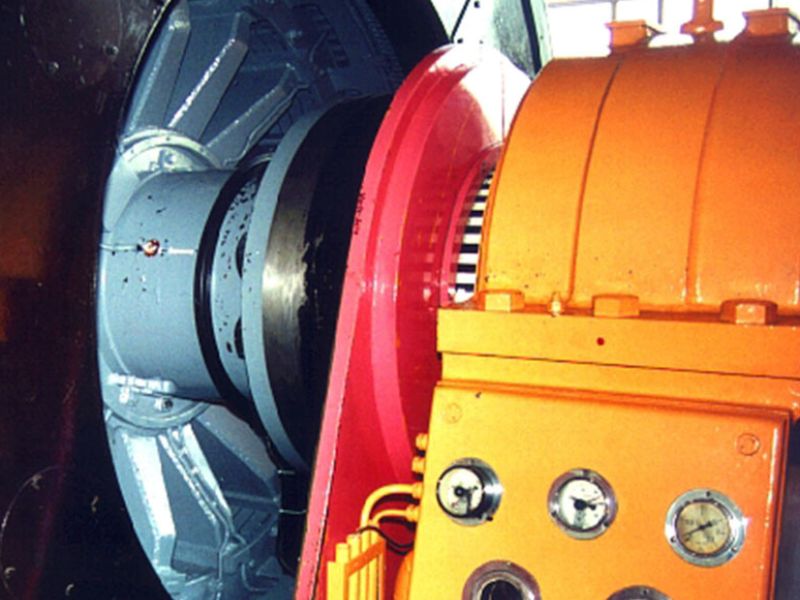

Oil-free gas and air compression has proven itself as a fundamental component of many industrial applications. Because the production of high-quality compressed gas or compressed air is indispensable for the performance standards of numerous processes, MANNER Sensortelemetrie is constantly developing new measurement applications to refine these systems.

With the help of MANNER Sensortelemetrie sensors, measuring rotor temperatures is child’s play. To protect against exceeding the permissible rotor and winding temperatures, we have been working with manufacturers and operators of electric motors and generators for many years to optimize the monitoring of thermal loads.

For monitoring and protecting automated production facilities, MANNER Sensortelemetrie offers miniaturized applications for recording a wide variety of drive outputs in order to immediately stop production operations if load limits are exceeded.

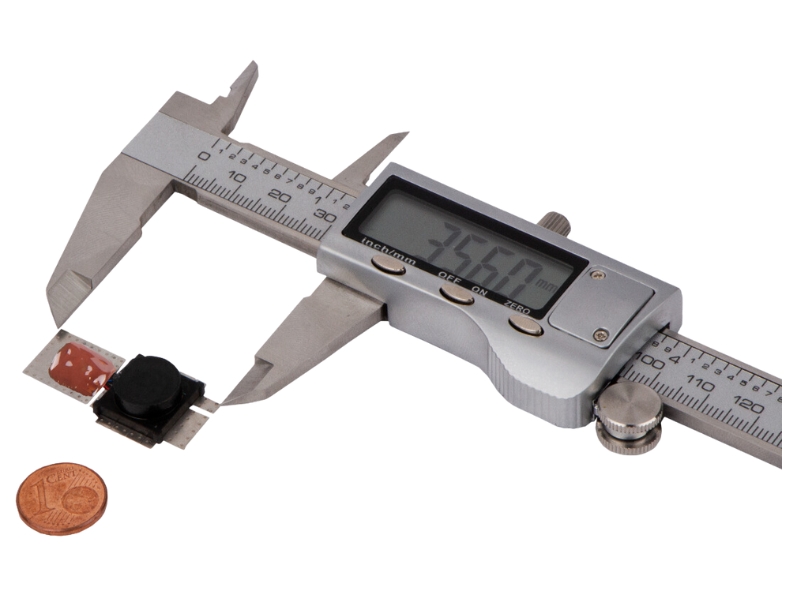

The TelMA torque sensor from MANNER Sensortelemetrie is a miniaturized, telemetric torsion sensor in stamp format that enables cost-effective and dynamic torque measurement for Industry 4.0 and machine monitoring.

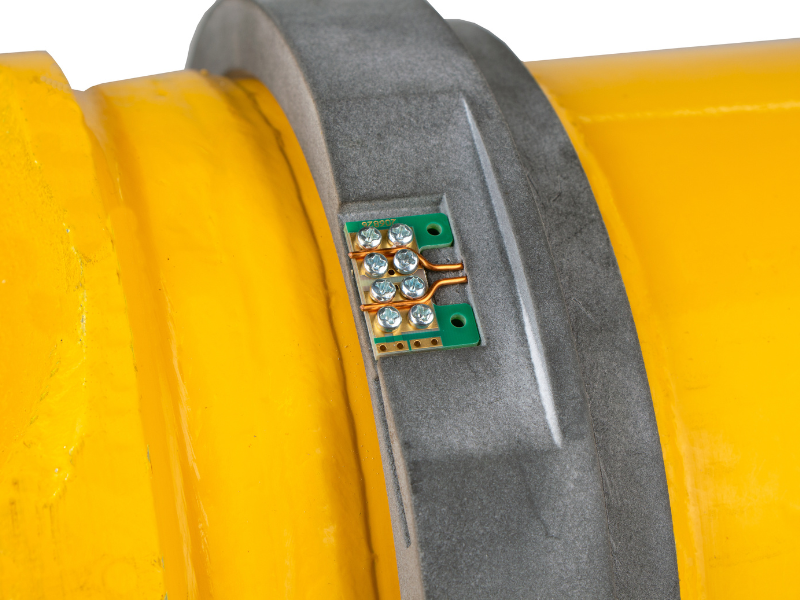

The weldable TelMAX Torque measurement system from MANNER Sensortelemetrie is an elegant method of torque measurement/monitoring on drive trains in the field and on machines (gearboxes, pumps, motors, marine drives, drive shafts).

The ProductAssistant

In a few steps to the optimal measuring system. Our product experts configure the optimal system composition according to your requirements and will be happy to prepare an individual offer for you.