New Generation of Non-Contact Temperature Measurement for Use in Machinery and Electric Motors

Accurate temperature measurement is of central importance in nearly all areas of mechanical and motor engineering for ensuring operational reliability. It not only provides essential data on the thermal stress of individual components, but also forms an indispensable foundation for the development and safeguarding of thermally stressed systems.

Particularly during the development phase, reliable temperature monitoring protects against overload and potential component failure. Additionally, it enables targeted optimization of system design and drive control under realistic conditions—a factor that remains irreplaceable despite advanced simulation models.

Challenges in Temperature Measurement

The operating environment places high demands on the measurement technology used: temperature measurements must be performed reliably and without interference in confined installation spaces, often in close proximity to thermally critical zones—such as the winding head of an electric motor. The systems used must therefore be miniaturized and integration-ready, while also being resistant to mechanical and electrical interference as well as thermal influences.

Flexible Integration of Rotor Electronics into the Smallest Installation Spaces

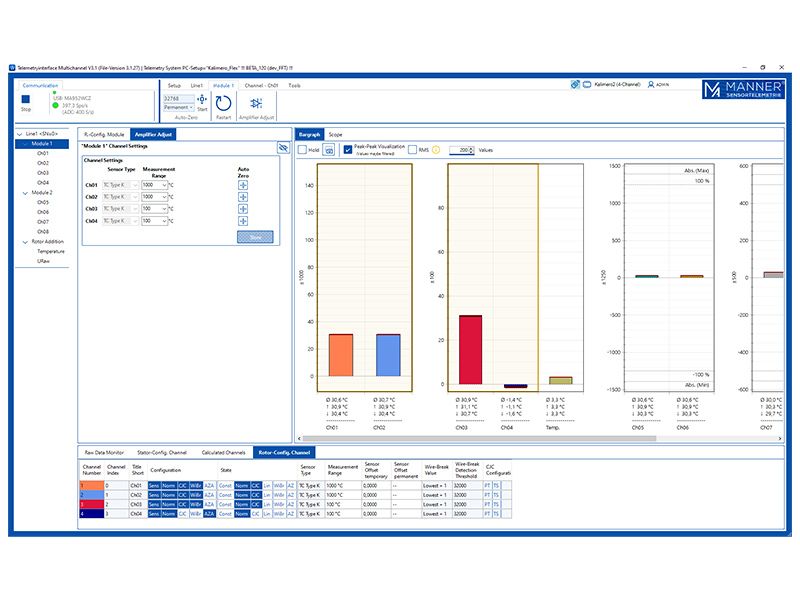

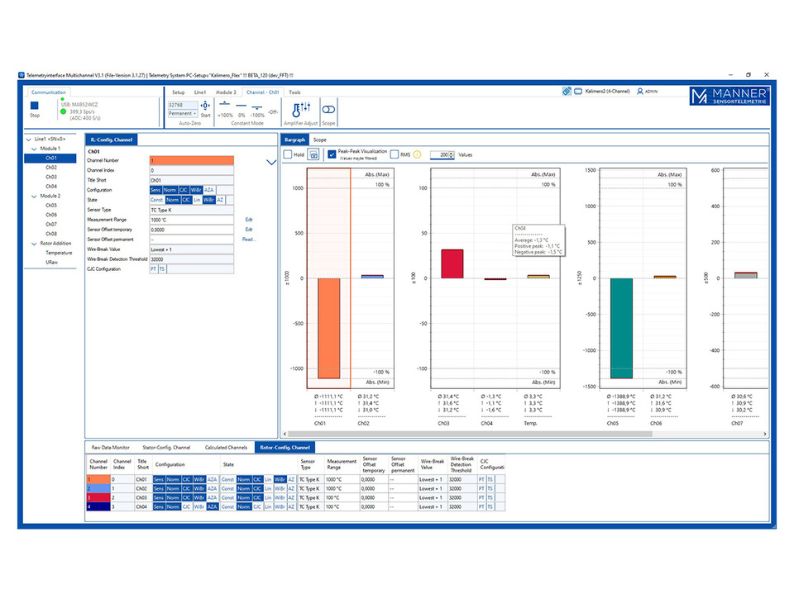

MANNER Sensortelemetrie GmbH addresses these challenges with its new generation of telemetry systems. The temperature amplifiers used are based on a highly compact, modular design. By combining several miniaturized amplifier modules, any mechanical form factor can be realized, enabling integration into any motor design. Additionally, the number of measurement channels can be flexibly adjusted for use in highly integrated applications.

Ambient Temperature Resistance of MANNER Sensor Telemetry

It is well known that power density in motors is increasing significantly—and continues to rise. This results in substantial heat exposure for the rotors. MANNER’s sensor telemetry systems are designed to withstand ambient temperatures of up to 200 °C in the rotor electronics.

The proven, robust inductive data transmission method used by MANNER also enables non-contact, wear-free transmission—even in rotating or multi-moving component assemblies. This technology guarantees maximum transmission reliability and flexibility, even in deeply integrated setups with minimal space.

The rotor electronics and the evaluation unit do not need to be paired. Calibration is stored in the rotor electronics, allowing the components to be used universally. This eliminates configuration errors such as incorrect CAN settings.

Technological Features of the New Generation

The current telemetry platform for temperature measurements offers:

- Maximum sampling rates of up to 400 samples/s

- Scalability up to 128 channels in the maximum configuration

- Software-based remote configuration of all relevant rotor parameters, including:

- Selection of sensor type (thermocouples, PT100, PT1000, strain gauges)

- Freely selectable measurement ranges

- Integrated cable break monitoring with configurable response behavior (positive/negative threshold or defined switching point for emergency shutdown)

- Thermocouple polarity setting

The system itself consists of the strain gauge for torque measurement, the sensor signal amplifier, and the OptiMA evaluation unit. Depending on the installation environment, the desired sensor signal amplifier can be flexibly chosen as an end-of-shaft version or applied on the shaft with a rotor antenna kit.

Practical Functions for Rapid Commissioning

In practice, applications are often implemented under tight time constraints. In the haste of setup, connection errors—such as reversed polarity of thermocouples or torque sensors—can occur. These errors are frustrating and may only be correctable during post-processing. MANNER offers a practical solution: with a simple software click, input reversal can be activated directly on the amplifier—without mechanical intervention or rewiring, which is often already sealed. This saves valuable time and significantly increases commissioning safety.

Optional Feature: WLAN

Commissioning, setup, and service functions via WLAN using a smartphone or tablet greatly simplify system handling.

System Integration as a Key Factor

A core advantage of MANNER solutions lies in their practical system integration. The telemetry systems can be seamlessly integrated into existing drive concepts or test bench infrastructures—both mechanically and electronically. This enables fast commissioning and significantly reduces development cycles.

Conclusion

With its new generation of non-contact temperature amplifiers, MANNER Sensortelemetrie offers a powerful and flexibly configurable system for demanding temperature measurements in machinery and motors. The combination of miniaturization, high data rates, robust inductive data transmission, and software-supported configuration makes the system an ideal solution for modern development and testing processes.

MANNER Sensortelemetrie GmbH

Ihr Partner für berührungslose Messlösungen im Hochleistungsbereich